Copyright © 2020 Fujian Xinyun Machinery Development Co.,Ltd. All rights reserved. Site Map Powered by iwonder.cn

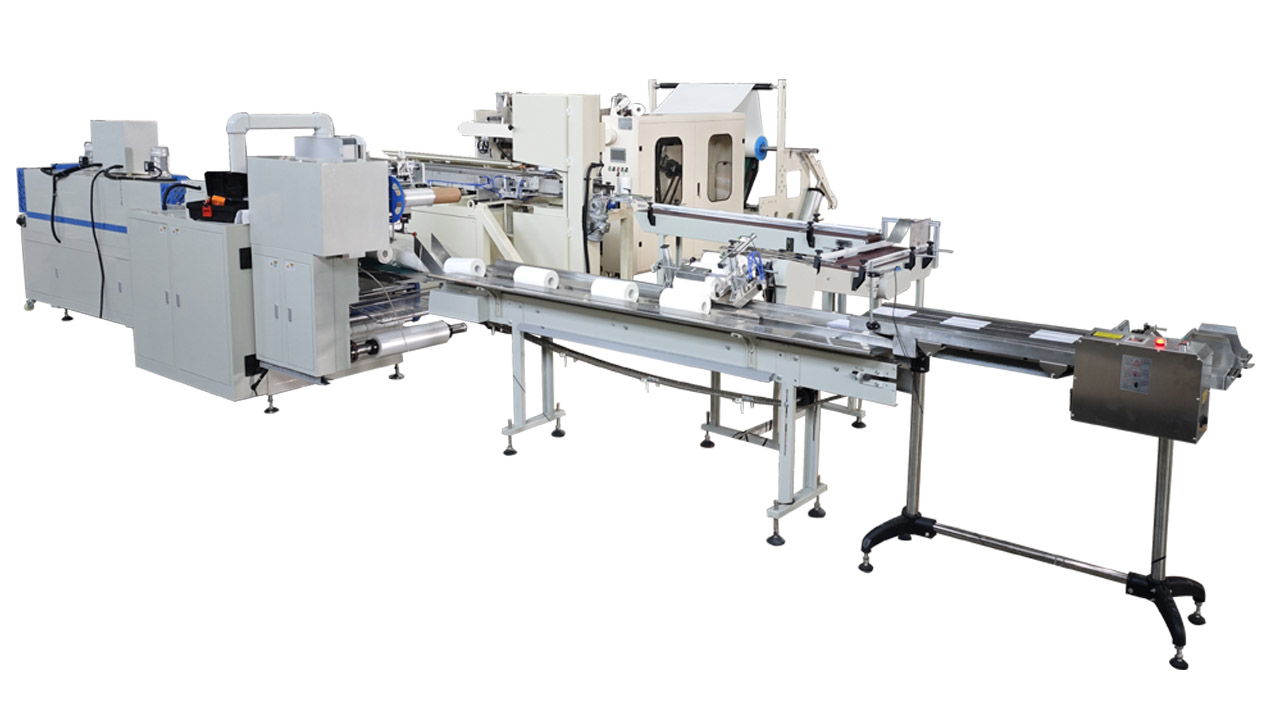

This production line consists of Fully Automatic Rewinding Machine, automatic band saw machine and automatic shrink packing machine. From the jumbo roll into the finished rolls, the whole line work smoothly and run stable, saving the labor cost and reducing the labor strength. It’s best choice for the producing hygienic paper products.

XY-TQ-A-G Automatic labeling non woven viscose fabric making machine production line

Technical performance characteristic:

This production line consists of Wall Type Automatic Rewinding Machine, Band saw cutting machine and automatic shrink packing machine From jumbo roll paper into the finished rollers, the whole line work smoothly and run stable, saving the labor cost and reducing the labor strength. It’s best choice for the producing maxi roll paper products.

Automatic maxi roll paper rewinding machine

Functions and Features

1. This machine is for making toilet paper rolls, the whole structure is wall-type, which make machine running stable at high speed, and noiseless.

2. Perforation distance is adjustable to meet different distance needs.

3. Automatic core feeding system, automatic pushing the log after rewinding, then rewinding the new log again.

4. Automatic edge-trimming, glue spraying and sealing synchronously in one time. Leaving 10-18mm tail, easy to rewind again, so reducing shortcut waste and save the cost.

5. Adopts international advanced PLC programmable controlling technique, man-machine interface operation, data set and parametric fault shows on touch screen.

6. Adopts 4 pieces high Precision spiral knives, low noise, clear perforation, adopt gearbox to have bigger range.

7. Two wall type back stands, pneumatic lifting system, with wide driving flat belts; each jumbo roll can be adjusted independently.

8. Adopt jogging switches for wearing the paper, easy and safe to operate.

XU-AI-400 Automatic band saw cutting machine

Main Technical Parameters:

Main Technical Parameters:

| Speed | 80-100 |

Toilet log length | ≦2850mm(it can be made according to customer request) |

Finished toilet roll diameter | 70-130mm |

Finished toilet roll length | ≦300mm |

Cutting tolerance | ±1.5mm |

Power | 5kw 380V 50Hz |

| Cutting blade | band saw blade(Size 3750*50*0.5) |

Overall size | 4300x1500x2100mm |

| Weight | 1100KG |

XY-TN-269 Automatic maxi roll paper shrink packing machine

Application:

Automatic cutting sealing and temperature shrink machine is using shrink film package the product out, after heating, the shrink film will shrink the wrap coiler in a package. In order to fully display the item, with protection and increase the beauty and sense value.

Main Technical Parameters:

| Speed | 15-20 bages/min |

| Packing size | 200-400mm(L)×200-400mm(W)×60-250mm(H) |

| Power | 1.35KW 220V 50Hz and 9.6Kw 380V 50Hz |

| Overall size | 3100mm(L)×750mm(W)×1360mm(H) |

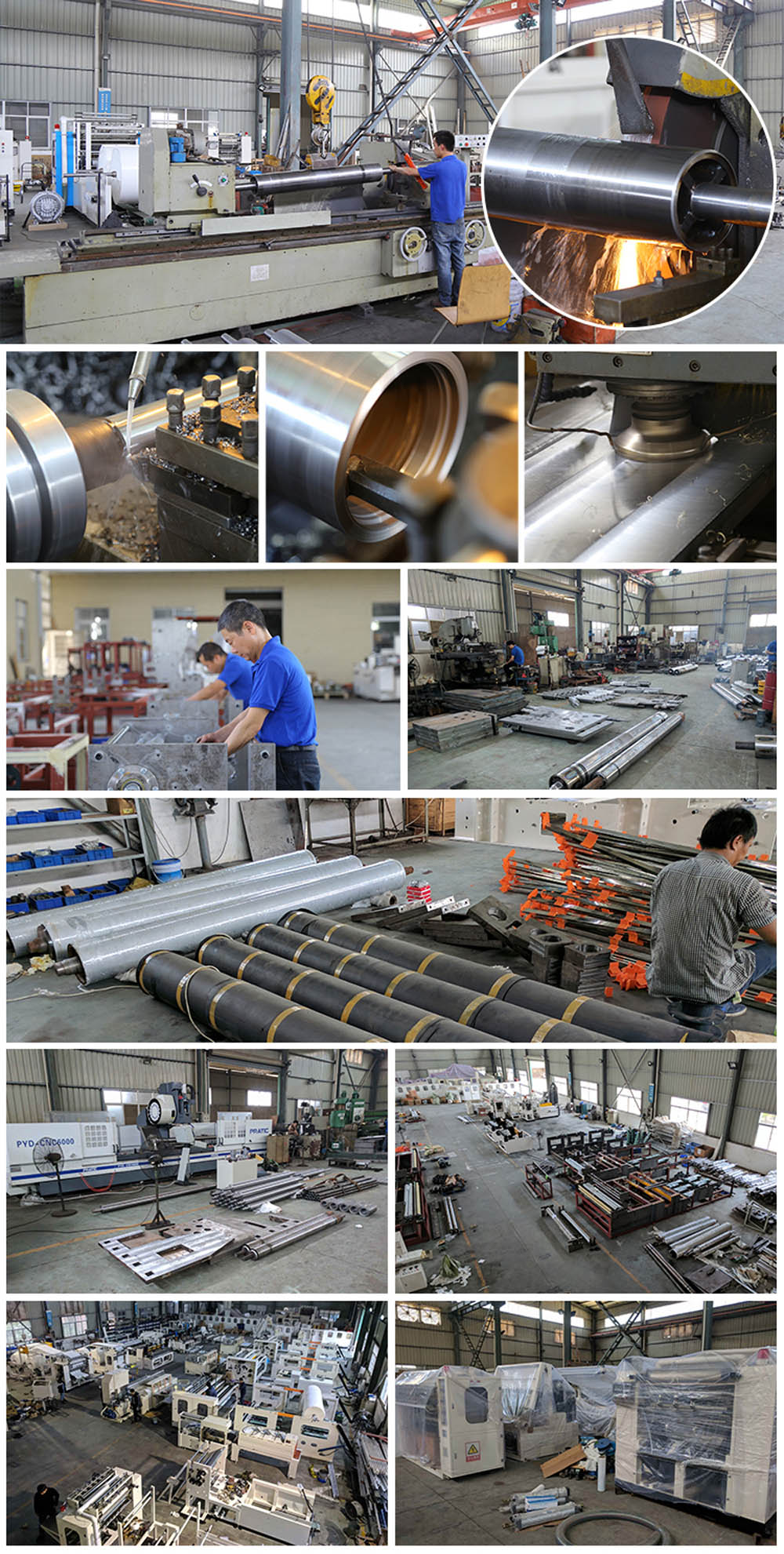

Fujian Xinyun Machinery Development Co.,Ltd is good at Paper Converting Machinery Manufacturer.

Professional supplier of:

1) Toilet Paper Machine (1.2m--2.8m width of parent roll, Customize Service)

2) Roll Kitchen Paper Towel Machine (1.2m--2.8m width of parent roll, Customize Service)

3) Facial Tissue Machine (2-8 output lanes)

4 )Napkin Paper machine(L-fold, 1/4-fold, 1/6-fold, 1/8-fold and other multi-fold type)

5) Hand Towel Paper Machine(C-fold, V-fold and N/Z fold type)

6) Pocket Tissue Machine(mini and standard size)

7) All kinds of Tissue Paper Cutting and Packing Machine

8) Another Household Paper Equipments and Production Line.

Welcome to contact us to get more details !

We can design the machine according to your request.

By continuing to use the site you agree to our privacy policy.