Copyright © 2020 Fujian Xinyun Machinery Development Co.,Ltd. All rights reserved. Site Map Powered by iwonder.cn

Which Machine Is Used To Make Paper?

Paper is one of the most commonly used materials in the world.Whether it's for printing, packaging, hygiene products,or cleaning purposes,paper plays a crucial role in our daily lives. But how is paper made,and what machines are used in the process?In this article,we will explore the various paper machines involved in paper production,with a focus on specific machines designed for making different types of tissue paper products,such as toilet paper, kitchen towel paper, facial tissues, hand towel paper and napkin tissue

A paper machine is an industrial device used to manufacture paper, and it performs several complex tasks during the paper production process. These machines are designed to transform raw materials, like wood pulp and recycled paper, into the finished product, be it for writing, cleaning, or hygiene purposes. Let’s dive into the world of paper machines and discover the different types of machines used for making paper products.

A paper machine is an industrial device used in the paper manufacturing process. It typically consists of multiple components, including a forming section, press section, drying section, and winding section. Each section plays a key role in converting raw materials into finished paper products.

The process of making paper typically involves the following steps:

Pulping: Raw materials like wood or recycled paper are broken down into fibers, which are then suspended in water to create pulp.

Forming: The pulp is spread onto a moving screen, where it forms a wet sheet of paper.

Pressing: The wet paper sheet passes through rollers that remove excess water, compact the fibers, and create the desired thickness.

Drying: The paper is dried through heated rollers or steam to remove any remaining moisture.

Winding: The finished paper is rolled onto large rolls, ready for further processing or packaging.

Different types of paper machines are used depending on the specific paper product being produced. For example, a toilet paper machine will have specific requirements for softness, absorbency, and strength, while a kitchen towel machine will need to focus on durability and absorbency.

There are many different kinds of paper machines tailored for specific types of paper products. Below, we will explore some of the most commonly used machines for making various tissue paper products.

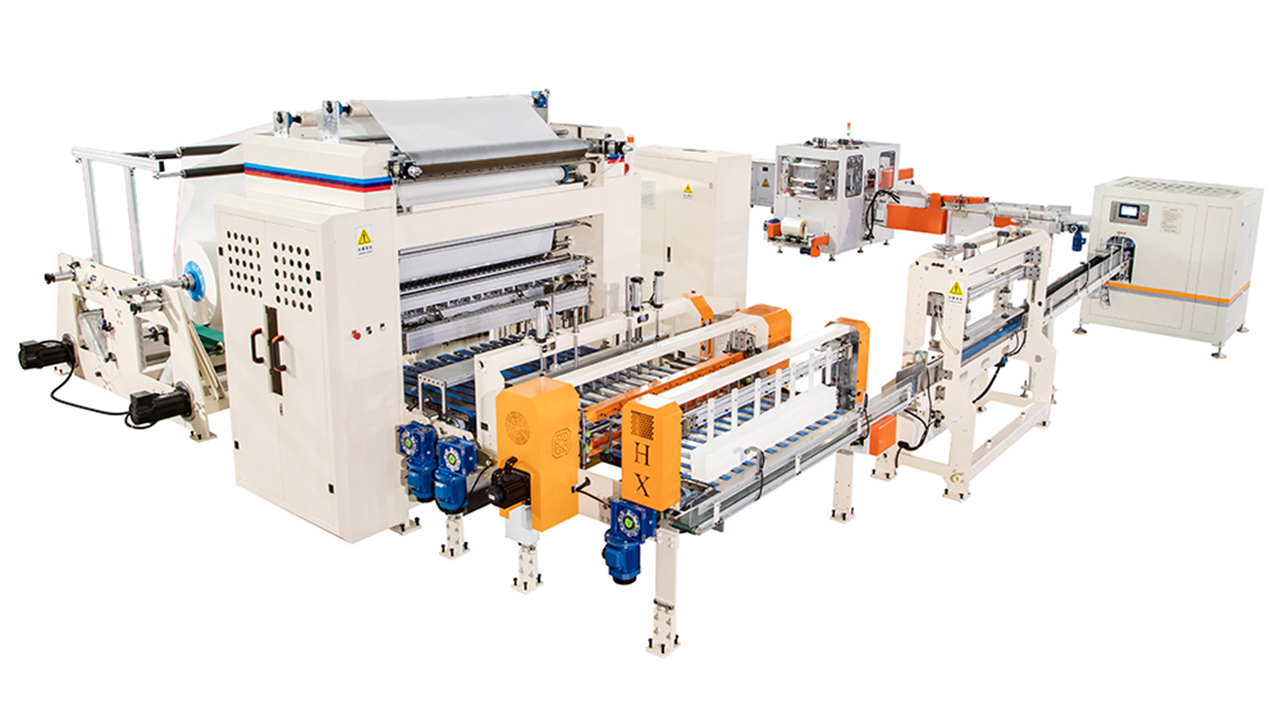

A toilet paper and kitchen towel paper machine is designed specifically to produce soft, absorbent paper for personal hygiene use. These machines use advanced technologies to produce toilet paper with specific qualities, such as softness, strength, and thickness. The production process involves turning raw materials like wood pulp into soft rolls of toilet paper.

High-speed production: Toilet paper machines are capable of producing large volumes of paper at high speeds.

Softness: The machine uses multiple rollers and air jets to ensure the paper is soft enough for use.

Embossing: Many toilet tissue machines include embossing rollers to create decorative patterns on the paper,which can increase absorbency and visual appeal.

Glue lamination:Many kitchen towel paper include glue lamination device device to Good water absorption and not easy to break

The cost of a toilet tissue making machine can vary based on its level of automation, speed, and features. Small toilet paper making machine prices are more affordable for smaller operations but may have lower production capacities.

2. Facial Tissue Machine

2. Facial Tissue MachineA facial tissue machine is used to produce soft, thin tissues designed for personal care. These machines require high precision to ensure that the facial tissues are gentle on the skin and free from defects. The machine typically produces tissue rolls that are then cut, folded, and packaged for consumer use.

Softness: The machine uses multiple rollers and drying sections to produce a soft texture that is ideal for facial tissues.

Quality Control: Facial tissue machines include quality control features to ensure each sheet is free from holes or defects.

Folding and Packaging: The machine automatically folds and packages the tissues for retail sale.

The facial tissue machine is typically more expensive than other tissue paper machines due to its focus on high-quality production.

3. Hand Towel Machine

3. Hand Towel MachineA hand towel machine is designed to produce paper towels specifically for drying hands. These towels are typically thinner and less absorbent than kitchen towels, but they need to be durable enough to handle the job in commercial and public settings.

High-speed production: These machines are designed to produce paper towels quickly and efficiently.

Perforation and folding: The paper is perforated and folded to facilitate easy dispensing and use in public restrooms or workplaces.

Strength: Hand towel machines focus on creating paper towels that are strong enough to dry hands without tearing.

The cost of a hand towel machine will depend on the production capacity, level of automation, and any additional features such as embossing or packaging capabilities.

A napkin paper machine is used to produce paper napkins, which are commonly used in restaurants, cafes, and households. These machines are capable of producing single-ply or multi-ply napkins that are soft and absorbent.

Multiple plies: These machines can produce multi-ply napkins for increased strength and absorbency.

Folding: The machine can fold the napkins in various configurations, such as quarter-fold, half-fold, or inter-fold.

Customization: Many napkin paper machines offer the option to emboss the paper with designs or patterns.

The cost of a napkin paper machine varies depending on the size and features, with fully automated machines being more expensive.

For smaller businesses or startups, a small scale tissue paper making machine can be a great option. These machines are designed for lower-volume production but still deliver high-quality paper products.

Lower production capacity: These machines produce paper at a slower pace compared to industrial-scale machines.

Affordable pricing: Small scale tissue paper making machines are more affordable than large, fully automated machines.

Versatility: These machines can produce various types of tissue paper, including toilet paper, facial tissues, and kitchen towels.

Small toilet paper making machine prices can vary depending on the brand, features, and capacity but generally cost between $10,000 and $50,000.

For those on a tight budget, second-hand tissue paper making machines can provide an affordable alternative to purchasing new equipment. Used machines are typically less expensive and can be found through online marketplaces like OLX or specialized equipment dealers.

Condition: It's essential to inspect the machine thoroughly for wear and tear, especially the rollers and drying sections.

Warranty: Some used machines come with warranties or service agreements, which can provide peace of mind.

Upgrades: Some second-hand machines may require upgrades or refurbishing to meet modern production standards.

Tissue paper making machine prices in China for second-hand machines can be much lower compared to new equipment, but buyers should be cautious about the condition and history of the machines.

A tissue paper mill is an industrial facility where paper products are produced on a large scale. The mill houses multiple paper machines for different types of paper production, including toilet paper, kitchen towels, and facial tissues. Setting up a tissue paper mill requires substantial investment in land, machinery, raw materials, and labor. However, it can be a highly profitable venture due to the demand for tissue paper products worldwide.

Multiple paper machines: A tissue paper mill will typically have several paper machines dedicated to different products.

Raw material processing: The mill processes raw materials like wood pulp or recycled paper into usable pulp for paper production.

Large-scale production: Tissue paper mills are designed for high-volume production, often running 24/7.

The cost of setting up a tissue paper mill can be significant, ranging from several hundred thousand to millions of dollars depending on the size and scale of operations.

Making paper involves sophisticated machinery and processes. Paper machines are crucial in transforming raw materials like wood pulp or recycled paper into a wide variety of paper products, including toilet paper, kitchen towels, facial tissues, and napkins. Whether you're looking for a small scale tissue paper making machine, a fully automatic tissue paper making machine, or even a second-hand tissue paper making machine, there are numerous options available to suit different production needs and budgets.

Investing in the right paper machine can help businesses meet consumer demand for high-quality paper products while ensuring efficiency and cost-effectiveness. As demand for tissue paper continues to grow, understanding the machines and technologies involved in production will be essential for success in the paper manufacturing industry.

By continuing to use the site you agree to our privacy policy.