Copyright © 2020 Fujian Xinyun Machinery Development Co.,Ltd. All rights reserved. Site Map Powered by iwonder.cn

Band saw paper cutting machines are an essential tool in the paper industry, especially for cutting toilet paper rolls with precision and efficiency. In this article, we’ll explore how band saw paper cutters work, the factors that affect their performance, and how to ensure the best cutting quality.

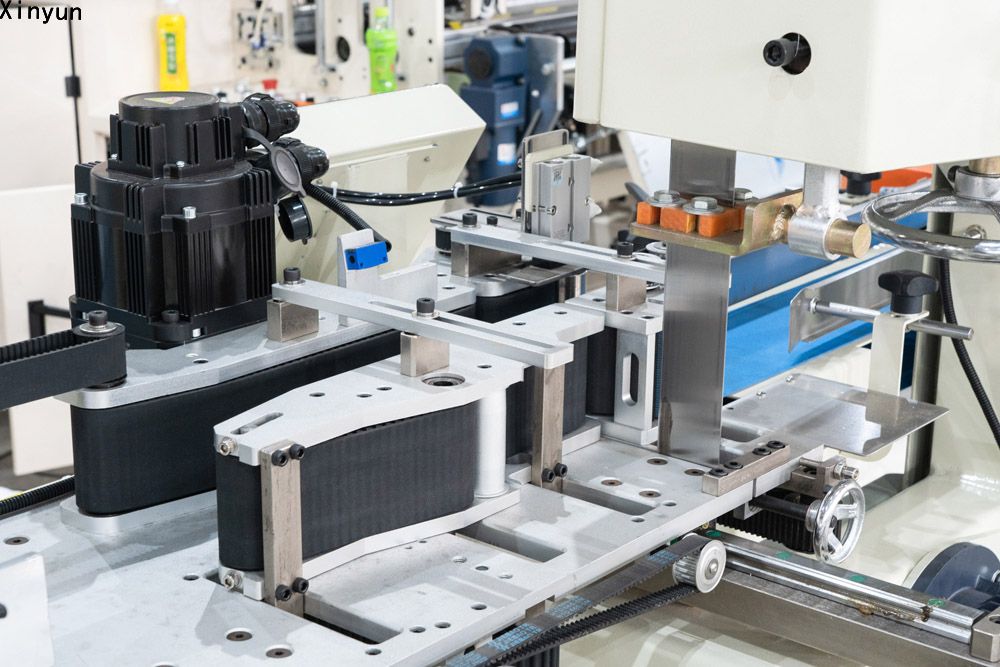

A band saw paper cutter is a specialized machine used to slice large rolls of toilet paper into smaller, uniform sheets. Unlike traditional paper cutting machines, which use a fixed blade or rotary knife, band saw cutters use a continuous loop of sharp metal to make clean, precise cuts. This method allows for smoother, more consistent cutting and is particularly useful for cutting soft materials like toilet paper.

The band saw paper cutter operates by using a band of steel that moves in a continuous loop. The paper roll is fed into the machine, and as it passes through the saw, the band’s sharp edge slices through the paper. The machine typically uses a set of rollers to apply pressure to the paper, ensuring that it remains in place as the blade moves through.

The primary advantage of the band saw design is its ability to cut cleanly without causing excessive pressure or fraying of the paper. This results in smoother edges, reducing waste and ensuring a more uniform product.

Several factors can influence the quality of the cuts made by a band saw paper cutter. Here are the main elements to consider:

The sharpness of the blade is critical for achieving clean cuts. A dull blade will cause more friction, leading to jagged cuts, increased wear on the machine, and higher power consumption. A sharp, well-maintained blade ensures smooth cuts and reduces the effort needed for each slice. The design of the blade, including the bevel and width, also impacts cutting precision.

The pressure applied to the paper stack plays a crucial role in the accuracy of the cut. If the pressure is too low, the paper may shift during cutting, resulting in uneven sheets. On the other hand, excessive pressure can deform the paper and cause misalignment. It’s important to adjust the pressure based on the type of paper and the desired cut. Softer papers may require more pressure, while firmer, thicker papers may need less.

Different types of paper require different cutting parameters. Soft, thin paper is more prone to deformation, so it often requires higher pressure to prevent the top layers from bending. For thicker or harder paper, a lower pressure setting is preferable, as excessive pressure can cause the blade to move off course. Additionally, the sharpness of the blade should be adjusted to suit the type of paper being cut. A sharper blade helps overcome the resistance of harder papers, ensuring a clean cut.

The balance between blade sharpness and pressure is key to achieving high-quality cuts. If the blade is not sharp enough, it may pull or tear the paper, leading to uneven cuts and wasted material. Similarly, if the pressure is not correctly calibrated, the paper may become misshapen, or the blade may fail to cut through the paper evenly.

Manufacturers should ensure that their band saw cutters are properly maintained. Regular sharpening and adjustment of the pressure settings based on the type of paper being cut are essential for maintaining optimal performance.

Band saw paper cutting machines are a vital tool in the production of toilet paper. Their ability to provide clean, precise cuts is crucial for ensuring high-quality products that meet consumer expectations. By paying attention to blade sharpness, pressure, and the type of paper, manufacturers can ensure consistent cutting performance and reduce waste.

If you're looking for advanced solutions for your paper cutting needs, Xinyun offers high-performance band saw cutters that can help you improve cutting precision and efficiency. Contact us today to learn more about how we can enhance your production process.

By continuing to use the site you agree to our privacy policy.